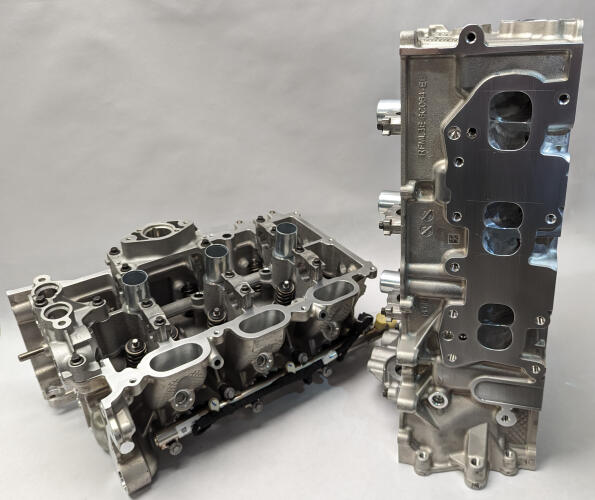

LIVERNOIS MOTORSPORTS GEN 2 3.5L ECOBOOST STAGE 3 RACE HEADS - CUSTOMER CORE

The Livernois Stage 3 product line is built for customers who are looking for products that offer a no compromise approach. The components and services used in these products are in most cases custom designed proprietary parts that are based off of years of development and the latest in racing technology. These proprietary designs and parts are available only through Livernois Motorsports. Each and every product in this line has been developed and tested in a rigorous R&D process to produce only the highest quality most durable products on the market. The extensive design time that goes into making a product for this line involves a complete and systematic approach to the entire product and its lifecycle. Each part is designed and tested to work together as a system to maximize power and durability. This Livernois line of products includes parts from industry leaders in their fields such as Manley, Callies, ARP, Carillo, Diamond, Ross and Clevite to name a few. Every aspect of the design, testing and final product machining and assembly are handled in house. This allows for complete control of the entire process start to finish. The latest in technologies are used in the design and testing of these products and components, including FEA (Finite Element Analysis), CFD (Computational Fluid Dynamics), as well as some of the latest CNC and CAD technologies available.

About Livernois Motorsports

Livernois Motorsports & Engineering has become best-known for revolutionary tuning and high-end performance products for late model Ford, Mopar and GM vehicles. The company is proud of its deep roots in the automotive and motorsports industry dating back to its original founding in 1949. Since then the company has expanded its product line to include tuning and performance components for desert racing, SCCA and drag racing. Livernois Motorsports is proud to engineer, test and manufacture its products in the USA.

Livernois Motorsports cylinder heads are built with the automotive enthusiast in mind. Each has the performance, reliability, and power to back it up. All Livernois cylinder heads are designed, engineered, and manufactured in-house at our facility in Dearborn Heights, MI. 100% American Made!

They are designed around our custom engineered CNC porting program. Each and every cylinder head is tested for maximum airflow and efficiency by our highly trained cylinder head technicians. From there they head for further testing on the dyno to verify CFM and airflow numbers and efficiency. Valve job is needed for proper valve sealing.

Finished cylinder heads are sent to the CNC department where the heads will be CNC ported and verified. Our development process is what ensures a very high-end product that offers better performance across the spectrum. The combination of increased airflow, Livernois proprietary components, and hardware they are able to achieve the maximum performance that enthusiasts crave.

These cylinder heads are built around Livernois Motorsports years of racing experience and combine all the knowledge of our extensive development background as well. This is how we're able to offer cylinder head packages that are unmatched in their performance.

Included Services and Components

- 5 axis CNC machined

- Fully assembled

- Custom CNC valve job

- Custom Stainless Intake Valves

- Custom High Temp Exotic Alloy Exhaust Valves

- Livernois Motorsports Upgraded valve springs

- Upgraded valve seals, retainers, locks

(Livernois Motorsports GEN 2 3.5 EcoBoost Cylinder Head Flow Chart)

*Flown On 1020 Flow Bench*

| Cam Lift | Intake | Exhaust |

| .050" | 55.0 | 40.8 |

| .100" | 110.0 | 89.4 |

| .150" | 150.1 | 135.9 |

| .200" | 192.0 | 161.5 |

| .250" | 225.8 | 184.3 |

| .300" | 253.5 | 199.1 |

| .350" | 270.5 | 208.6 |

| .400" | 282.6 | 215.9 |

| .450" | 289.0 | 220.3 |

| .500" | 292.2 | 225.0 |

| .550" | 295.8 | 227.0 |

| .600" | 298.0 | 231.1 |

- 2017 Ford Expedition EL King Ranch 3.5 Liter Turbocharged

- 2017 Ford Expedition EL Limited 3.5 Liter Turbocharged

- 2017 Ford Expedition EL Platinum 3.5 Liter Turbocharged

- 2017 Ford Expedition EL SSV 3.5 Liter Turbocharged

- 2017 Ford Expedition EL XL 3.5 Liter Turbocharged

- 2017 Ford Expedition EL XLT 3.5 Liter Turbocharged

- 2017 Ford Expedition King Ranch 3.5 Liter Turbocharged

- 2020-2021 Ford Expedition King Ranch 3.5 Liter Turbocharged

- 2017-2021 Ford Expedition Limited 3.5 Liter Turbocharged

- 2020-2021 Ford Expedition Max King Ranch 3.5 Liter Turbocharged

- 2018-2021 Ford Expedition Max Limited 3.5 Liter Turbocharged

- 2018-2021 Ford Expedition Max Platinum 3.5 Liter Turbocharged

- 2018-2021 Ford Expedition Max SSV 3.5 Liter Turbocharged

- 2018-2019 Ford Expedition Max XL 3.5 Liter Turbocharged

- 2018-2021 Ford Expedition Max XLT 3.5 Liter Turbocharged

- 2017-2021 Ford Expedition Platinum 3.5 Liter Turbocharged

- 2017-2021 Ford Expedition SSV 3.5 Liter Turbocharged

- 2017-2019 Ford Expedition XL 3.5 Liter Turbocharged

- 2017-2021 Ford Expedition XLT 3.5 Liter Turbocharged

- 2019-2021 Lincoln Navigator Base 3.5 Liter Turbocharged

- 2018-2021 Lincoln Navigator Black Label 3.5 Liter Turbocharged

- 2018-2021 Lincoln Navigator L Black Label 3.5 Liter Turbocharged

- 2020-2021 Lincoln Navigator L Livery 3.5 Liter Turbocharged

- 2017-2021 Lincoln Navigator L Reserve 3.5 Liter Turbocharged

- 2017-2019 Lincoln Navigator L Select 3.5 Liter Turbocharged

- 2018 Lincoln Navigator Premiere 3.5 Liter Turbocharged

- 2017-2021 Lincoln Navigator Reserve 3.5 Liter Turbocharged

- 2017-2019 Lincoln Navigator Select 3.5 Liter Turbocharged